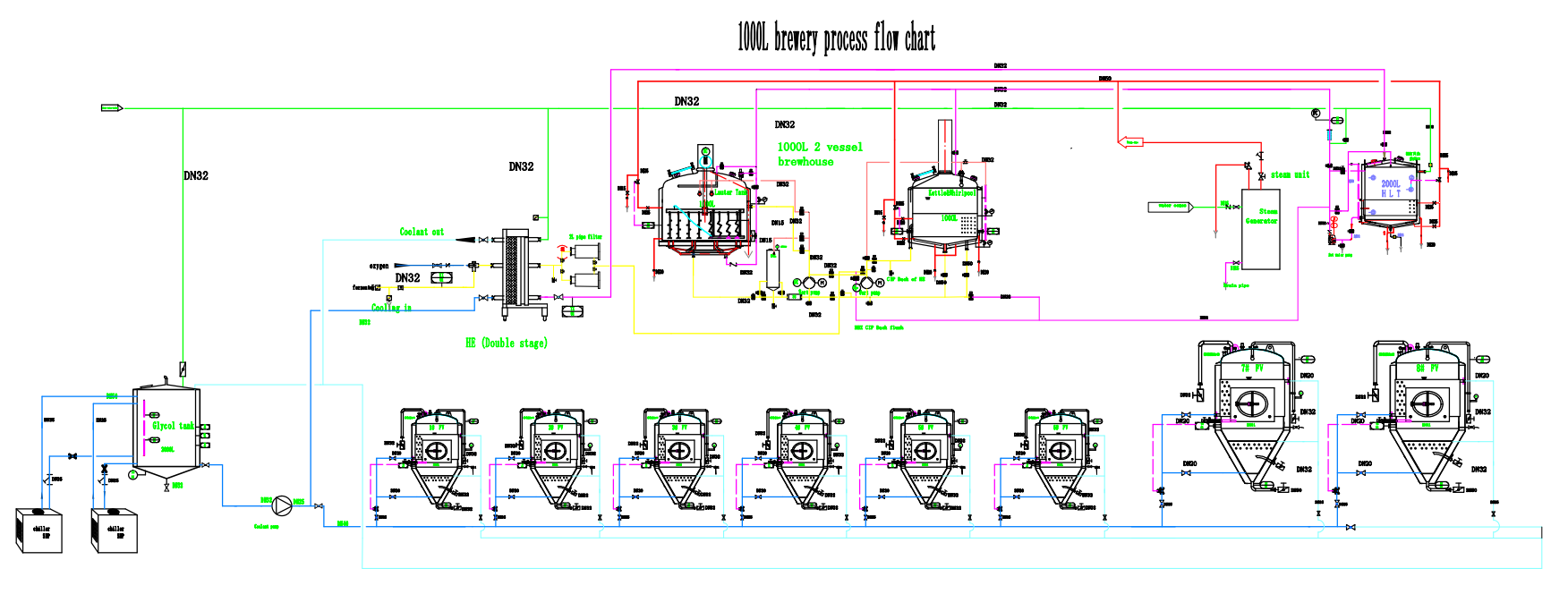

Icandelo 2: Siza kwenza ntoni kuyilo lweshishini lotywala?

2.1 Brewhouse: Ihambelana kakhulu nesicelo sakho sokwenza utywala.

Inxalenye ye-Brewhouse yeyona nto ibalulekileyo kwi-brewery epheleleyo, ehambelana ngokuthe ngqo ne-wort kunye nomgangatho webhiya.Uyilo lwendlu yotywala kufuneka lulandele ngqo iresiphi yakho yokwenza utywala, umz. umndilili womxhuzulane webhiya/iplato.Qinisekisa ukuba inkqubo ye-Mash okanye i-lautering inokugqitywa ngexesha elifanelekileyo.

Kanye njengesampulu ye-10BBL inkqubo yotywala.

Itanki yeLauter: Ububanzi betanki ye-lauter yi-1400mm, xa i-wort i-13.5 degrees, isixa sokutya kwe-malt yi-220KG, izixhobo ezisebenzisayo ukusebenza kakuhle ziyi-75%, kunye nobukhulu bomgca wengqolowa yi-290mm;indawo yokucoca yi-1.54m2, kunye nesantya sokucoca ngu-0.4m / s;Isantya sokuvula isihluzo se-12%, kwaye kukho i-6 wort channels kwi-lauter tank.

Ngenkxaso yezi parameters, kuyaqinisekiswa ukuba ixesha lokuhluza ligqityiwe ngaphakathi kweeyure eziyi-1.5, kwaye unokuqinisekisa ukuba unokufumana i-wort ecacileyo.

Xa i-wort iyi-16 plato, isixa sokutya yi-260KG, umthamo wetanki usebenzisa i-80%, kunye nobukhulu bebhedi yengqolowa yi-340mm.Oko kukuqinisekisa ukuba ubukhulu boluhlu lokucoca luhlangabezana neemfuno zokuthunga, aluchaphazeli isantya sokuhluza kwaye luqinisekisa ukusebenza kakuhle kwemveliso.Okokugqibela ukuphucula imveliso ngexesha leyunithi ngokunciphisa ixesha lokuhluza.

Iketile ebilisayo: Uyilo lwevolyum yeketile lusekwe kwi-wort ye-1360L yokubilisa, kwaye umthamo wokusetyenziswa yi-65%.Ngenxa yokuba i-wort concetration iphezulu kakhulu kumazwe angaphandle, ifom iya kuba ninzi kakhulu xa ibiliswa.Ukuze kuthintelwe i-foam ephuphumayo kwi-kettle ngexesha lokubilisa, sisebenzisa umsebenzi wokujikeleza okunyanzeliswayo ukuphucula izinga lokunyuka kwe-evaporation ukuqinisekisa ukuba izinga lokunyuka kwe-8-10% kunye nokuphucula ukubilisa.Ukujikeleza okunyanzeliswayo ngeketile kunceda ukunyusa ukukhuphuka, kunye nemeko ye-DMS kunye nomxholo ngaphakathi kwe-30PPM, iya kunciphisa ukulayishwa kobushushu kunye nokuqinisekisa ukuzinza kwe-chroma ye-wort kunye nokuphepha ukuphendulwa kwe-wort Maillard.

2.2 Ukusetyenziswa kwamandla asezantsi kwindawo yokuthengisa utywala

Inkqubo yeCondensor: Iketile ebilayo ithatha inkqubo yokubuyisela ukuthotywa komphunga, iya kunceda ekuphuculeni ukubuyiswa kwamanzi kunye nokugcina ukusetyenziswa kwamanzi kunye nombane kwishishini lonke.Ubushushu bokubuyisela amanzi ashushu malunga ne-85 ℃, kunye nomthamo wokubuyisela amanzi ashushu kwi-150L kwibhetshi nganye;Oko kuthetha ukuba iya konga i-electic 18kw ngebhetshi nganye yobushushu bamanzi ukusuka kwi-25-85℃.

I-Wort epholileyo: Indawo yokutshintshiselana kobushushu bewort ibala ngenkqubo yokugalela kwaye igqibe inkqubo yokupholisa ngemizuzu engama-30 ukuya kwengama-40, kunye nobushushu bamanzi ashushu kwi-85℃ emva kokutshintshiselana kweheax, ukusebenza kakuhle kotshintshiselwano lobushushu ngaphezu kwe-95%.Ngoko ke, siya kuqinisekisa ukubuyiswa kwamandla aphezulu kunye neendleko eziphantsi zokuvelisa.

2.3 Ukwenziwa lula kunye nokunciphisa ukugcinwa kwinkqubo yokwenziwa kwebhiya

2.3.1 Isihluzi esiphindwe kabini silungisiwe, xa umxhasi esenza ibhiya yehoppy kakhulu.Ngoko sizisa isiqinisekiso esihle kwi-plate heat exchanger, eyona nto inzima kakhulu yokucoca.

2.3.2 Ipompo ephindwe kabini iyimfuneko kwiyunithi ye-glycol, isiqinisekiso esihle xa kukho nasiphi na isicelo sokugcina, ipompo nganye inokutshintsha ngokulula ukugcina imveliso iqhubeka.

2.3.3 I-Dual chiller ilungiselelwe, ngenjongo efanayo njengempompo ye-glycol.

2.3.4 Impompo yeGlycol isebenzise impompo yoxinzelelo engaguqukiyo kwaye igcine uxinzelelo olufanayo kwimibhobho yeglycol yonke, khusela ivalve ye-soleniod kunye nokwandisa ubomi bokusebenzisa.

Zonke ezi nkcukacha zezomsebenzi ozinzile ngakumbi kwi-ruuning ye-brewery, kwaye izise amava alungileyo kwinkqubo yokusela.

Ixesha lokuposa: Sep-25-2023